Which Magnet Material Has the Best Corrosion Resistance for Fan Motors?

Selecting the right magnet material for fan motors is crucial for longevity in humid, salty, or chemically aggressive environments. Let’s break down the top three options and their corrosion resistance performance.

1. Neodymium (NdFeB) Magnets

-

Magnetic Strength: Unmatched (Up to 52 MGOe)

-

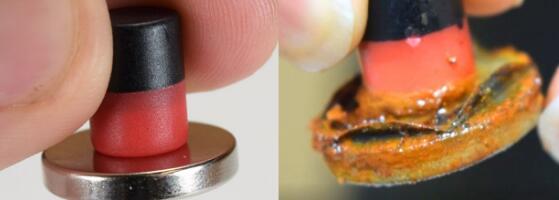

Corrosion Resistance: Poor – Requires nickel-copper-nickel (Ni-Cu-Ni) coatings to prevent rust. Uncoated NdFeB corrodes rapidly in humidity.

-

Cost: Moderate (coated versions)

-

Best For: Short-term, dry applications needing maximum power.

⚠️ Critical Weakness: Fails within weeks in 85% humidity without coatings.

2. Samarium Cobalt (SmCo) Magnets

-

Magnetic Strength: High (26–32 MGOe)

-

Corrosion Resistance: Exceptional – Naturally resistant to saltwater, acid rain, and temperatures up to 300°C. No coatings needed.

-

Cost: 2–3× higher than neodymium